ISO 9001 Certification – Annual Internal Audit Plan

An annual internal audit plan for ISO 9001 should cover all relevant processes, procedures, and requirements of the standard. Here is a general outline of what the plan should include:

Review the Quality Management System (QMS) documentation: Start by reviewing the QMS documentation, including the Quality Manual, procedures, work instructions, and records. This will help you understand the scope of the QMS and identify the processes that need to be audited.

Identify the audit objectives: The audit objectives should be based on the company's goals, customer requirements, and the ISO 9001 standard. These objectives should be measurable and specific, and should focus on identifying areas for improvement.

Determine the audit scope: The scope of the audit should include all the processes, departments, and locations that are part of the QMS. The scope should be defined based on the company's risk assessment and the importance of each process to the QMS.

Develop the audit checklist: The audit checklist should include all the requirements of the ISO 9001 standard, as well as any additional requirements that are specific to the company's QMS. The checklist should also include questions that focus on identifying areas for improvement.

Assign auditors: The audit team should be composed of qualified auditors who have the necessary knowledge and skills to audit the QMS processes. Assign auditors to each process, and ensure that they are independent and impartial.

Schedule the audits: Schedule the audits based on the company's needs and the availability of the auditors. The audits should be spaced out over the year to ensure that all processes are audited.

Conduct the audits: The audits should be conducted in accordance with the audit plan and checklist. The auditors should follow a structured approach, including opening and closing meetings, collecting evidence, and writing the audit report.

Report the findings: The audit findings should be reported to the relevant managers and process owners. The findings should be specific, measurable, and focused on areas for improvement.

Follow up on corrective actions: The process owners should develop corrective action plans to address the audit findings. The auditors should follow up on the corrective actions to ensure that they have been implemented effectively.

Review and update the audit plan: At the end of the year, review the audit plan and identify any areas that need to be updated or improved. This will ensure that the next year's audit plan is more effective and efficient.

How to get ISO 9001 Certification

Getting ISO 9001 certification is a long process; it may take a minimum of three to four months to complete the certification process. As an experienced ISO 9001 consultant , LMG can help you achieve the ISO 9001 certification process at a reasonable cost and a minimum timeframe.

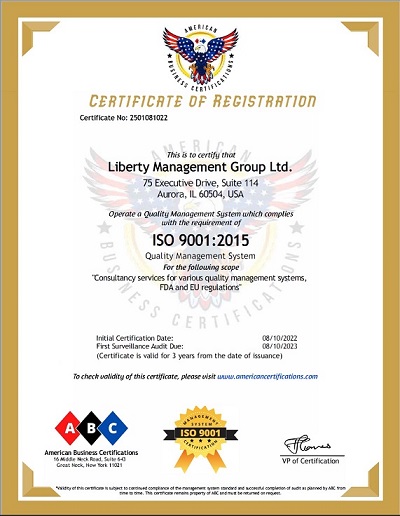

ISO 9001 Certificate

The international organization for standardization (ISO) only develops the standards, and certification is not a requirement. Still, manufacturing and service companies require a document to present to their customers as evidence of ISO 9001 implementation. Third-party certification bodies issue the ISO 9001 certificate as evidence of ISO implementation after conducting an audit per ISO guidelines.

Our Services include.

LIBERTY MANAGEMENT GROUP LTD.

Chicago

75 Executive Drive, Suite 114

Aurora, IL - 60504

Phone : (630) 270-2921

Fax : (815) 986-2632

E-mail : info@libertymanagement.us