Control Sample Register in Quality Control and Regulatory Compliance

In quality system regulations, a "control sample register" typically refers to a documented record or log that tracks the identification, location, and status of control samples used in various quality control processes within an organization. Control samples are representative samples of materials, products, or substances that are retained for the purpose of conducting quality testing and comparisons over time.

Control sample registers are important in quality management systems to ensure that consistent and accurate quality control practices are followed. Here's how a control sample register might be structured and used:

Sample Identification: Each control sample should be uniquely identified, often using a combination of codes, names, and/or descriptions that allow easy reference.

Product/Material Information: This includes details about the product or material being sampled, such as batch or lot number, manufacturing date, supplier information, and any other relevant identifiers.

Date of Sampling: Record the date when the control sample was collected from the production process.

Storage Location: Specify where the control sample is stored. This could be a dedicated storage area designed to maintain the integrity of the sample, such as a controlled environment with specific temperature and humidity conditions.

Sample Status: Indicate the current status of the sample, such as "approved," "pending testing," "rejected," etc.

Testing Schedule: If applicable, note when the sample should be tested and what tests should be performed on it.

Testing Results: Include the results of any quality control tests performed on the sample. This information helps track the sample's consistency over time and can provide insights into product/material quality.

Retention Duration: Specify how long the sample should be retained. This duration is often determined by regulations, industry standards, or internal company policies.

Disposition: Indicate the final disposition of the sample once its retention period expires. This could involve destruction, further testing, or other appropriate actions.

Audit Trail: Maintain a record of any changes made to the sample's status, testing results, or other relevant information. This ensures transparency and accountability.

Signatures and Approvals: If required, document the signatures or approvals of individuals responsible for managing the control sample and its associated data.

It's important to note that the specific requirements for control sample registers can vary depending on the industry, regulatory environment, and organizational policies. Industries such as pharmaceuticals, food and beverages, chemicals, and manufacturing often have stringent requirements for control sample management due to the critical nature of quality control in these sectors.

Control sample registers contribute to maintaining product consistency, identifying trends in quality, and demonstrating compliance with regulations and standards during audits and inspections.

How to get ISO 9001 Certification

Getting ISO 9001 certification is a long process; it may take a minimum of three to four months to complete the certification process. As an experienced ISO 9001 consultant , LMG can help you achieve the ISO 9001 certification process at a reasonable cost and a minimum timeframe.

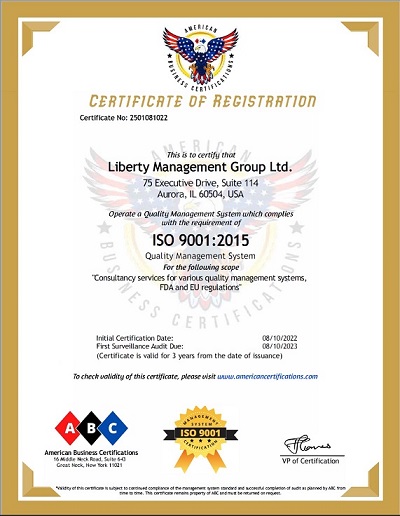

ISO 9001 Certificate

The International Organization for Standardization (ISO) only develops the standards, and certification is not a requirement. Still, manufacturing and service companies require a document to present to their customers as evidence of ISO 9001 implementation. Third-party certification bodies issue the ISO 9001 certificate as evidence of ISO implementation after conducting an audit per ISO guidelines.

Our Services include.

LIBERTY MANAGEMENT GROUP LTD.

Chicago

75 Executive Drive, Suite 114

Aurora, IL - 60504

Phone : (630) 270-2921

Fax : (815) 986-2632

E-mail : info@libertymanagement.us