ISO 9001 Certification – Risk Identification & Control

ISO 9001, the international standard for Quality Management Systems (QMS), requires organizations to identify and control risks that could impact the ability to consistently provide products or services that meet customer and regulatory requirements.

The ISO 9001 standard does not provide a specific document for risk identification and control, but rather it expects organizations to have a risk management process that is integrated into their QMS. The following are some key steps that an organization can take to identify and control risks as part of their QMS:

Establish a Risk Management Framework: Develop a risk management policy and process that outlines the organization's approach to risk management. This includes defining risk criteria, establishing risk management objectives, and identifying the resources needed for risk management.

Identify Risks: Conduct a risk assessment to identify potential risks to the organization's products or services, as well as risks related to the QMS itself. This can involve conducting a comprehensive analysis of the organization's processes and procedures, as well as external factors that could impact the organization.

Analyze Risks: Once risks have been identified, analyze their potential impact on the organization and the likelihood of them occurring. This can involve prioritizing risks based on their potential impact and likelihood.

Develop Risk Control Measures: Develop and implement risk control measures to mitigate or eliminate identified risks. This can involve developing procedures and processes to reduce the likelihood of risks occurring, as well as contingency plans to minimize the impact of risks if they do occur.

Monitor and Review: Continuously monitor and review the effectiveness of risk control measures and the overall risk management process. This can involve conducting regular risk assessments, analyzing data related to risks and risk control measures, and making necessary adjustments to the risk management process as needed.

It is important to note that ISO 9001 requires organizations to take a proactive approach to risk management rather than simply reacting to risks as they occur.

How to get ISO 9001 Certification

Getting ISO 9001 certification is a long process; it may take a minimum of three to four months to complete the certification process. As an experienced ISO 9001 consultant , LMG can help you achieve the ISO 9001 certification process at a reasonable cost and a minimum timeframe.

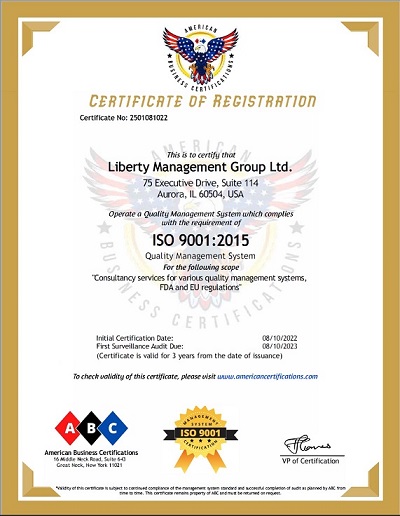

ISO 9001 Certificate

The international organization for standardization (ISO) only develops the standards, and certification is not a requirement. Still, manufacturing and service companies require a document to present to their customers as evidence of ISO 9001 implementation. Third-party certification bodies issue the ISO 9001 certificate as evidence of ISO implementation after conducting an audit per ISO guidelines.

Our Services include.

LIBERTY MANAGEMENT GROUP LTD.

Chicago

75 Executive Drive, Suite 114

Aurora, IL - 60504

Phone : (630) 270-2921

Fax : (815) 986-2632

E-mail : info@libertymanagement.us

New York

100 Duffy Avenue

Hicksville, NY 11801

Phone : (516) 244-2376

E-mail : newyork@libertymanagement.us