ISO 9001 Certification – Traceability Records

Traceability records are one of the records required in an ISO 9001 certification audit. These records provide evidence that the products or services being provided by the organization have been produced in accordance with the specified requirements and can be traced back to their origin. Traceability records typically include:

Material or component identification.

Date of receipt and use.

Supplier identification.

Quantity received and used.

Lot or batch numbers.

Process or work order numbers.

Inspection and test results.

Shipping and delivery information.

Customer identification and order numbers.

Traceability records are important for ensuring that products or services meet customer requirements and for identifying any potential issues or defects that may arise. These records can be used to identify the source of a problem, conduct a recall or investigation, or identify opportunities for improvement in the QMS.

How to get ISO 9001 Certification

Getting ISO 9001 certification is a long process; it may take a minimum of three to four months to complete the certification process. As an experienced ISO 9001 consultant , LMG can help you achieve the ISO 9001 certification process at a reasonable cost and a minimum timeframe.

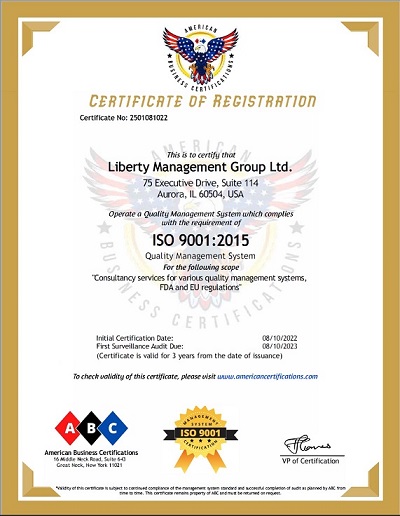

ISO 9001 Certificate

The international organization for standardization (ISO) only develops the standards, and certification is not a requirement. Still, manufacturing and service companies require a document to present to their customers as evidence of ISO 9001 implementation. Third-party certification bodies issue the ISO 9001 certificate as evidence of ISO implementation after conducting an audit per ISO guidelines.

Our Services include.

LIBERTY MANAGEMENT GROUP LTD.

Chicago

75 Executive Drive, Suite 114

Aurora, IL - 60504

Phone : (630) 270-2921

Fax : (815) 986-2632

E-mail : info@libertymanagement.us