Control Samples in Quality Control and Regulatory Compliance

A control sample is a physical sample of a product, material, or substance that is collected and retained for the purpose of comparison and quality testing. These samples serve as reference points to ensure that products and materials consistently meet established quality standards over time.

Key Concepts

Representative Sample: Control samples are carefully selected to be representative of a larger batch or lot of products or materials. This means that the control sample should accurately reflect the characteristics, properties, and composition of the entire batch.

Reference for Testing: Control samples act as a benchmark for conducting various quality control tests. By comparing the control sample to the products or materials from subsequent batches, manufacturers can determine if there are any deviations in quality or performance.

Long-Term Monitoring: Control samples are retained for a specified period of time, often determined by regulations, industry standards, or internal policies. Retaining samples over time allows for long-term monitoring of quality trends and helps identify any changes or variations in product quality.

Regulatory Compliance: Control samples play a crucial role in meeting regulatory requirements. Regulatory agencies may require companies to retain control samples to demonstrate that their products consistently meet quality standards and specifications.

Root Cause Analysis: If a quality issue arises, control samples can be used for root cause analysis. By comparing the control sample to the affected batch, manufacturers can investigate the source of the problem and take corrective actions.

Audits and Inspections: During regulatory audits or inspections, control samples serve as evidence of quality control practices. Auditors may review control sample records to ensure that the company is adhering to proper quality control procedures.

Validation and Verification: Control samples are used to validate and verify the accuracy of testing methods and equipment. By analyzing the control sample using established methods, laboratories can ensure that their testing procedures are reliable and consistent.

Quality Improvement: Monitoring control samples over time can provide insights into process improvements. If variations in quality are observed, companies can make adjustments to their manufacturing processes to maintain consistent quality levels.

Importance of Control Sample

Control samples are a fundamental aspect of quality management systems, especially in industries where product quality and safety are critical. By comparing new batches to control samples, companies can ensure that their products meet customer expectations, comply with regulations, and uphold their reputation for quality and reliability. Control sample registers help organizations keep track of these samples, their testing results, and their overall impact on the quality control process.

Control samples are a cornerstone of quality management systems, serving as reliable references for maintaining product quality, ensuring compliance, and continuously improving processes.

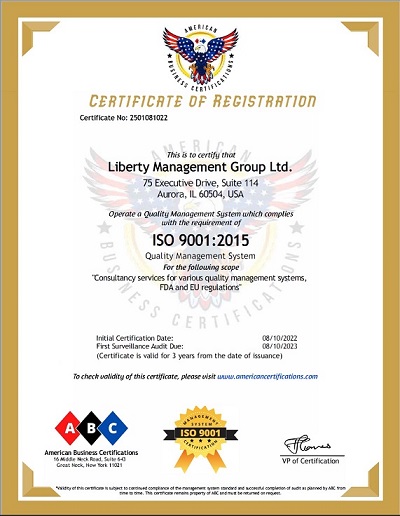

How to get ISO 9001 Certification

Getting ISO 9001 certification is a long process; it may take a minimum of three to four months to complete the certification process. As an experienced ISO 9001 consultant , LMG can help you achieve the ISO 9001 certification process at a reasonable cost and a minimum timeframe.

ISO 9001 Certificate

The International Organization for Standardization (ISO) only develops the standards, and certification is not a requirement. Still, manufacturing and service companies require a document to present to their customers as evidence of ISO 9001 implementation. Third-party certification bodies issue the ISO 9001 certificate as evidence of ISO implementation after conducting an audit per ISO guidelines.

Our Services include.

LIBERTY MANAGEMENT GROUP LTD.

Chicago

75 Executive Drive, Suite 114

Aurora, IL - 60504

Phone : (630) 270-2921

Fax : (815) 986-2632

E-mail : info@libertymanagement.us